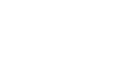

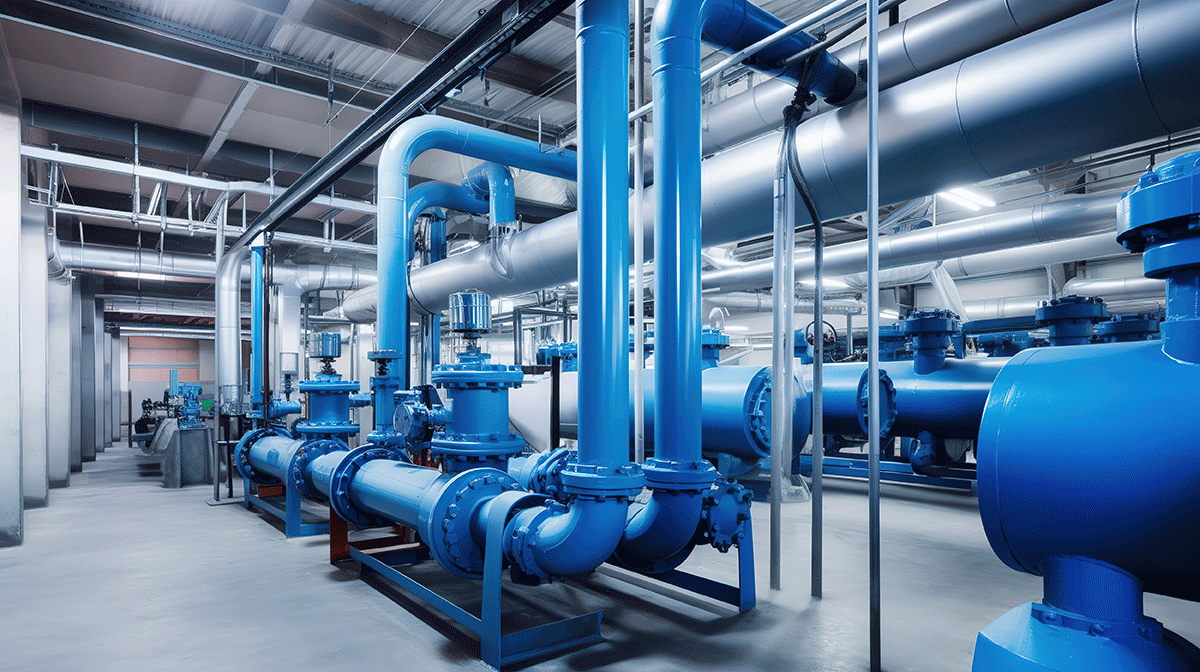

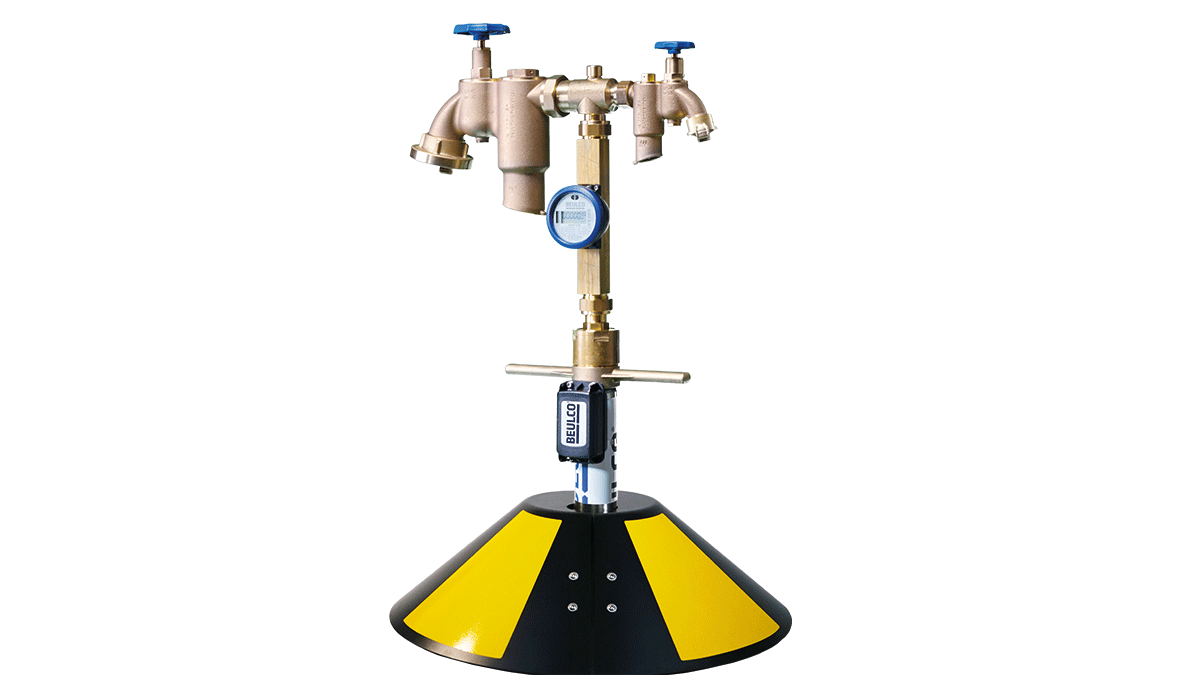

From the water extraction facility to the central safety device at the transfer point (system separator), the water supply company is responsible. Strict compliance with the requirements of the German Drinking Water Ordinance (TrinkwV) is mandatory, and when planning, installing, and operating transfer points from a public drinking water supply network via hydrants, the Technical Regulations of the DVGW (Worksheet W 408 and Supplementary Sheet B1) must be adhered to.

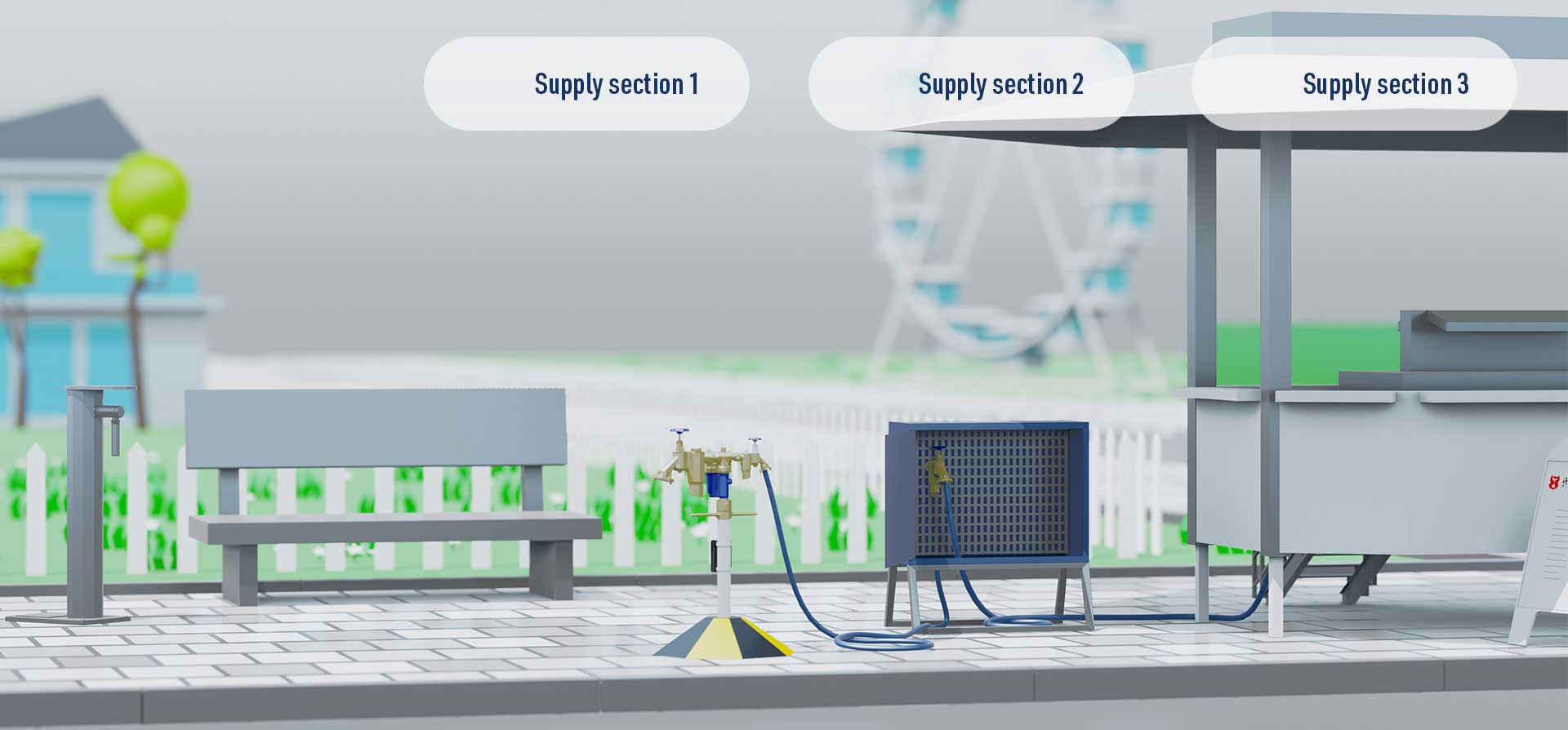

The water supplier ensures, with considerable effort, the quality and purity of the drinking water, which is then passed on under the responsibility of the operator of the distribution system.