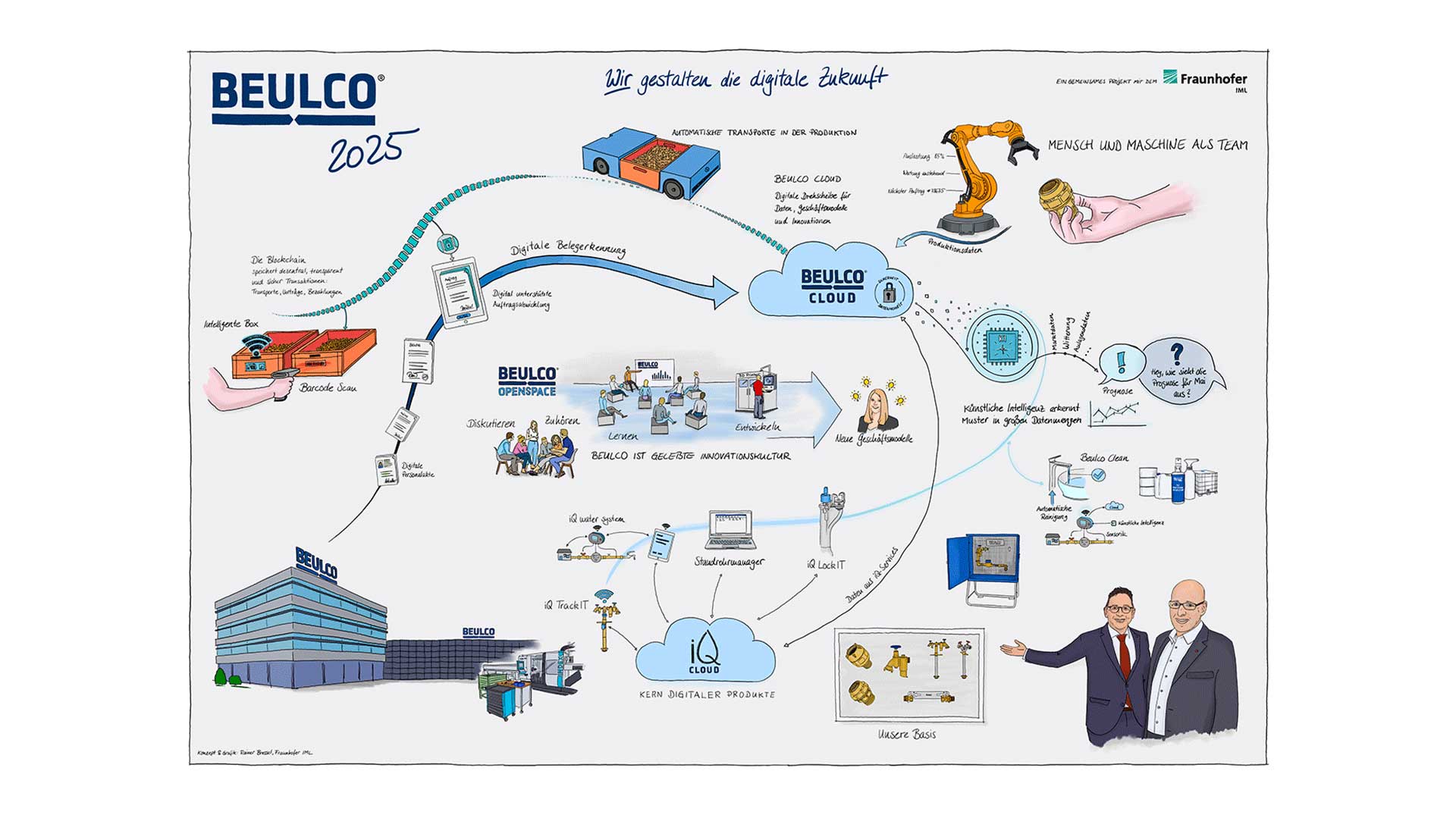

Shaping the digital future

with agility.

In the era of the digital revolution, technology has permanently changed the foundations of the business world. Companies are faced with the challenge of redesigning their processes, services and interactions with customers and partners in order to remain competitive. Digitalization has not only proven to be an indispensable component, but also a key driver of innovation and growth. The digitalization strategy outlines the roadmap for integrating technology into all aspects of the business.

A well-thought-out digitalization strategy is not only a response to technological developments, but also a way of putting customers and partners at the heart of business activities. It enables dynamic adaptation to changing expectations and needs and thus creates a foundation for long-term success and growth in the digital age.

People and expertise are the key resources that determine the success of digitalization. For this reason, the focus is on corporate culture and agile organization as drivers and catalysts of digitalization.